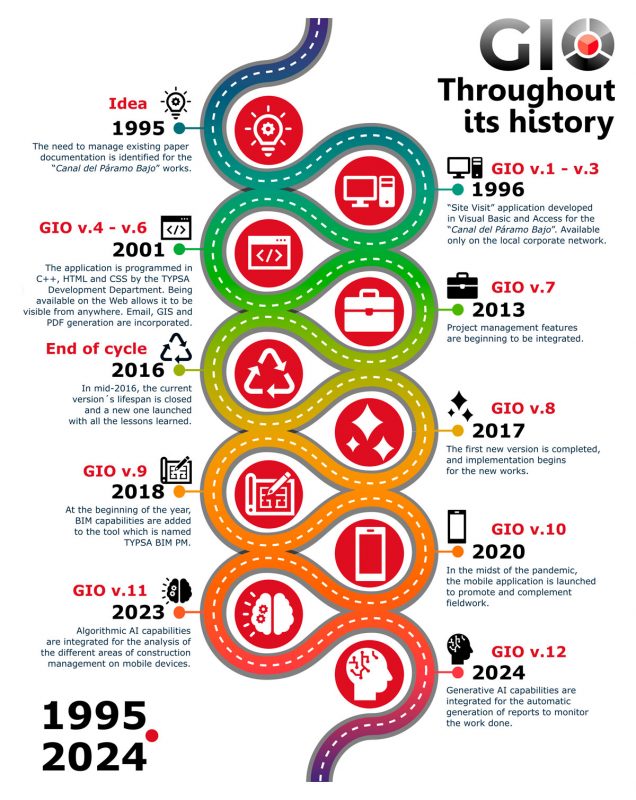

GIO is an Expert Construction Management System with a proven track record over time. 2025 will mark 30 years since the idea was conceived, a magnificent proposal for innovation, the capacities of which are continually expanding with technological advances.

Value proposition maintained over time

Over the last two decades, the system has been used in more than 550 contracts in different disciplines, across more than 30 countries, exceeding the value of supervised contracts of 40 billion euros. During this time, more than 16 TB of information has been recorded and stored for our clients.

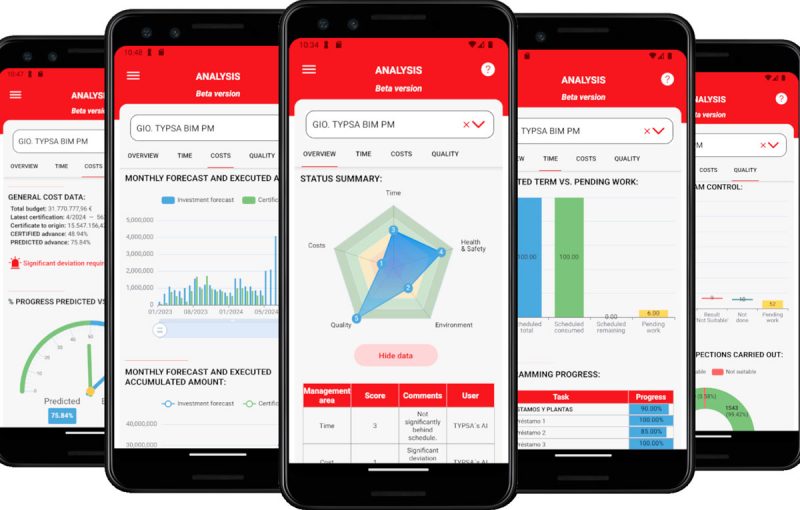

GIO is made up of a web platform and a mobile application, which has functionalities to operate on and off-line. Tools include those for managing scope, deadlines, costs, quality, health and safety, environment, resources, communications and include powerful graphic tools for data presentation and consultation, with options to filter and extract any information recorded.

Capturing the reality of the work: real-time data, work progress, resources, incidents and inspections.

GIO is completely embedded in our work methodology, and extensively tested in works of all kinds. Success is evident among our clients, who consider that TYPSA offers an outstanding service as reflected in satisfaction surveys, in which consistently high scores are achieved.

The application for mobile devices allows information to be collected onsite by our field inspectors which is synchronised with the database in real time, providing management with accurate information on the progress of the work, the machinery, the workforce used by the contractor, and incidents, if any.

From the mobile application we can also carry out quality, environmental or health and safety inspections. These inspections are use pre-established checklists that include the most relevant aspects, outlined in the inspection test plan (ITP). Through data and photographs, the inspection reports prepared by TYPSA have a higher added value than others made without these means because the client can see for themselves, that their requirements are actually being met, since these reports collect the evidence of what is being reviewed.

Inspection reports, daily site reports, machinery control and photographs are automatically incorporated into the system and linked to the model´s elements. Inspectors can stay on site most of the day, dramatically improving the effectiveness of their control function.

Moreover, all of the above, has been done without office-based work. This is very significant and must be understood properly: the system has allowed us to eliminate all the work with little added value done previously (transferring the handwritten parts to Word, downloading and archiving photographs, scanning the inspection sheets, etc.), allowing our inspectors to spend approximately 30% more time in the field, collecting information for our clients.

Dhaka-Assulia Elevated Expressway, first use of GIO in Bangladesh

Dhaka-Assulia Elevated Expressway, first use of GIO in Bangladesh

To get an idea of the magnitude of the challenges undertaken and the costs avoided, -not only economic but also environmental-, we only need to look at one of our works in Bangladesh. In two and a half years of work, our staff overseeing the Dhaka-Assulia Elevated Expressway have made 18,000 inspection reports. Not a single sheet of paper has been used on this enormous inspection process, nor have we scanned any documents or downloaded from cameras or phones any of the 150,000 photographs that have been taken to issue our daily activity reports or our quality, environmental or health and safety reports.

Structured information: status of client requirements for any element of the work

A key aspect for our clients is to check that their requirements are being met, in terms of quality, environmental protection or workers safety, for example. The TYPSA methodology, based on the control of work units, the assignment of data and documents to these elements and the emphasis on providing accurate information about them, has been successfully transmitted to our software from the start. Today, with the numerous technological advances produced over these thirty years of development, this approach is more valid and effective than ever.

For our clients, it is key to check that their requirements, in terms of quality, environmental protection or worker safety, are being met. GIO is the tool which allows them to effortlessly view this information from their mobile telephone.

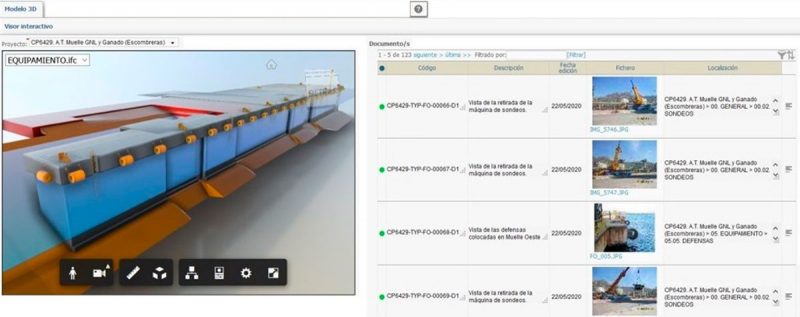

The use of location filters and the GIS and BIM modules, which relate all the documentation and data collected on site to their referenced construction element, allow our clients to obtain exact information from each point of the works. Moreover, these features, do not require additional work from our technical staff, since, once again, our technology allows the incorporation of data directly from the field into the models.

Structured information is the key to GIO’s success, as it allows access to data from any element of the work in multiple ways and at any time during the asset’s life cycle, according to the user’s needs.

In simple terms, whether on a 2D or 3D model, or by direct consultation, we can access all the documentation relating to a structure, to the stack No. 2 of this structure or to the pile no. 4 of the foundation of said pile: its drawings; the data from drilling or cross-hole tests; the inspections carried out during excavation, the placement of the reinforcement or the concreting; the photographs of all the processes; the means provided, both human and machinery; the communications between those involved, with the instructions of the construction manager or any other information. In short, all the documentation that can explain the status of that element today and at any time during the rest of the asset’s lifespan.

Universal tool

As shown in the figure describing the main features of GIO, we have used the tool in more than 30 countries. This means having met the needs, requirements and particular characteristics of very different clients who, however, have understood and accepted the extraordinary capabilities of our software and, also, of our work methodology.

Over 50 nationalities, with their different cultures and ways of understanding construction, have used GIO successfully.

Over 15,000 people have used the software, of more than 50 nationalities; from the Philippines to Chile and from Sweden to Uganda; people from different cultures and with different approaches to the construction industry have used or are using GIO successfully. Furthermore, despite the immense potential hidden behind its screens, it is very easy to understand and apply. TYPSA, always committed to quality, also provides continuous training for its technical staff, providing ongoing training in its working system and the application of GIO thereto.

Infrastructure lifespan

The information collected at GIO is the result of the work done by TYPSA during its contract, however it does belong to our clients.

It is in TYPSA’s DNA to always provide the best service to its clients, which is why we keep the information at their disposal for much longer than required legally or by contract.

As we have mentioned, the system currently stores 16 TB of information and remains available to our clients for long periods of time, beyond the legal deadlines established in the different countries in which we operate. Thus, the entire system becomes a very important source of information when the project goes, within its lifespan, to the maintenance stage, and even, much later, to closure.

In the “TYPSA spirit” of providing the best service, we can establish three key aspects:

- The information contained in GIO can be transferred to other software as and when the client so requires.

- All information is delivered, at the end of the contract, by electronic means.

- The client continues to have the information on our platform for periods of time much longer than those established legally and even contractually.

Automated report generation

Our technical staff on site, who usually must make reports for our clients, have key tools for generating them. Monthly reports should be used as an example: photographic reports, summaries of the status and results of the inspection point programs, economic status and monitoring of compliance with deadlines must usually be included. GIO provides information and graphic results on all these aspects, without requiring additional work in the office.

Innovation and Adaptability

Since its creation, GIO has proven to be a flexible and adaptable system, continuously integrating the latest technologies to improve its functionalities.

GIO performs information analysis using AI. Generative AI is also used to synthesise the work done, at the user’s demand. We are convinced that this field of development will continue to provide us with very surprising new features in the coming years.

In this line of innovation and adaptation to the latest technologies, we must mention the most recent advances with the integration of Artificial Intelligence (AI), which enriches the system with extraordinary abilities, facilitating the quick and convenient provision of information about the work done on site.

The ability to operate offline is another of the many features that make the system an indispensable tool for work supervision tasks. This functionality ensures that users can access and update information, regardless of connectivity conditions.

Powerful Analysis Tools

One of GIO’s most prominent features is its ability to effectively analyse and represent data. AI tools, for analysing the available data and reprocessing the information loaded into the system, facilitate informed and timely decision-making. This capacity for detailed analysis is crucial to keep projects within the established deadlines and costs, and with the quality required by the construction developer.

With our mobile application, the construction manager or the developer can view in real time the documentation generated by the system, such as meeting minutes, permits or licenses, contracts, reports, etc. Essential construction data, such as important dates, milestones or main managers can be consulted. There is also the option to graphically view the status of the work and the analysis that our AI carries out on the status of key management areas, such as deadline, cost and quality, with automatic valuation alerts.

Nokian TYRES, Spain, the first project in which the mobile application was implemented

Nokian TYRES, Spain, the first project in which the mobile application was implemented

The return on investment

Indeed, 30 years of sustained investment effort is not cheap. Leading the deployment of all the technologies that have emerged in this time is more than a strategic commitment. The TYPSA group´s philosophy is to stay at the forefront of engineering worldwide.

More than a strategic commitment. It is part of the essence of TYPSA to stay at the forefront of knowledge, working methods and software in all aspects of engineering.

Clearly, there is an undeniable reputational return, for example, even today, in most of the countries in which we work, it is very rare to see an engineering company using tools of this type on site. Only TYPSA applies them systematically in its construction supervision contracts.

We can of course evaluate the return that this investment has had: as we have seen, there are evaluable parameters in terms of resource cost savings. Other very considerable costs, such as those derived from the NON-use of external software are, perhaps, more difficult to apply with certainty, but are still valuable. The calculated return for this investment, considering only the 100 largest works, in terms of the economic value of our contracts, is €5.7 for every euro invested, more than 600%.

Success stories

In all the TYPSA divisions involved in the work, there are so many significant success stories that it is difficult to choose which to mention.

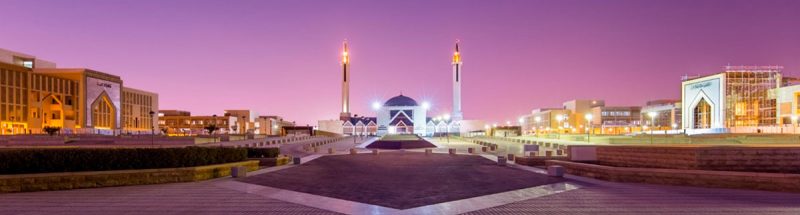

When we consider the greatest success stories of GIO, we logically think of the major contracts, such as the 400 km of railway that we oversee in Arabia for our client Saudi Arabian Railway (SAR), for whom we have collected an astounding 400,000 documents, and, without leaving this country, the documentary control of the Islamic University of Riyadh (50,000 documents). In Bangladesh, the previously mentioned Dhaka-Assulia Elevated Expressway, (220,000 documents and growing), where a team of 20 site engineers works hard to document the work in day and night shifts, and in India, the construction of the Kanpur and Agra subways (125,000 documents) with up to 487 registered users.

Islamic University of Riyadh, Saudi Arabia, first use of GIO in Arabia

Islamic University of Riyadh, Saudi Arabia, first use of GIO in Arabia

We believe, however, that we must also pay attention to the success of small contracts, where there are only one or two people who, not without effort, are able, using GIO, to prepare daily work reports and carry out as many inspections as necessary for work control. A typical example of these contracts is optional building management.

In Spain, the Barajas airport, the Chamartín railway station or the supervision of the port of Gijón (200,000 records); in Peru, the ports of El Callao, Piura and Pisco and, in Ecuador, the Manduriacu dam, where a team of dedicated colleagues engineered the closure of this reservoir in the middle of the jungle. Brazil, Mexico, wind turbines, highways and high-speed railways, subways… The list of success stories would be almost as extensive as the more than 600 works that have used it over the years.

It is worth mentioning, in particular, the Health and Safety Coordination work that TYPSA carries out in large public and private works, in which, through very capable and experienced teams, using GIO to evaluate situations and document them through reports and minutes, we fulfil the objective of protecting the health and guaranteeing the safety of workers.

The Future of GIO

Looking to the future, GIO continues to evolve to meet the changing needs of the construction industry. With its vision and constant focus on innovation and efficiency, GIO is well positioned to continue to be an essential tool for managing construction projects for years to come. Always considering the possibilities of improving work supervision and control processes, which are already excellent, we continue reducing redundant or lower value tasks and replacing them with others that contribute more to our clients through the incorporation of more AI tools in analysis, new applications in terms of risk management in construction, or the inclusion of 2D and 3D tools for internal development by TYPSA.

GIO is very well positioned to continue to be an essential tool for the management of construction projects in the coming years, with vision and constant focus on innovation and efficiency.

GIO facilitates the management of scope, deadlines and costs, with a proactive approach to the environment, quality and safety of workers. All these tools allow project managers to have a complete and detailed view of every aspect of the work, ensuring that all elements are managed efficiently and effectively.

In short, GIO has proven to be a comprehensive and adaptable solution that has stood the test of time. With 30 years of experience and continuous technological evolution, it continues to be a vital tool for the efficient management of construction projects.