Circular economy is an opposing concept to that of the predominant “linear economy” model, in which natural resources are extracted, transformed into commercial products and ultimately disposed of as waste. Circular economy gives importance to rethinking production systems and consumerism, promoting actions to reduce dependence on natural resource extraction and to reduce environmental impact, while encouraging innovation and the creation of new economic opportunities. In general, the objective is to maintain products, components and materials in a continuous cycle of use and reuse, avoiding waste, maximising efficiency and promoting the restoration/preservation of the planet’s biogeochemical cycles.

In the area of wastewater treatment, treated effluent is often discharged into bodies of water, which means that wastewater treatment plants (WWTP) are almost exclusively designed according to legislation governing water resource protection. In addition, it is well known that many of the existing wastewater treatment plants in Brazil have operational problems, often due to design deficiencies and in the execution of works. This in turn leads to an increase in treatment costs, a decrease in efficiency and, in some cases, non-compliance with environmental legislation.

Additionally, solid (sifted waste, sludge and foam) and gaseous (biogas and volatile emissions) by-products generated during treatment usually end up in landfills or combustion in the atmosphere. Although these are allowed by Brazilian legislation, it is still unclear as to whether they are the most appropriate, given the possible environmental impacts on the atmosphere, soil and groundwater. In this context, the role of the circular economy in preserving the planet’s biogeochemical cycles, in particular the nitrogen and phosphorus cycles, is reinforced.

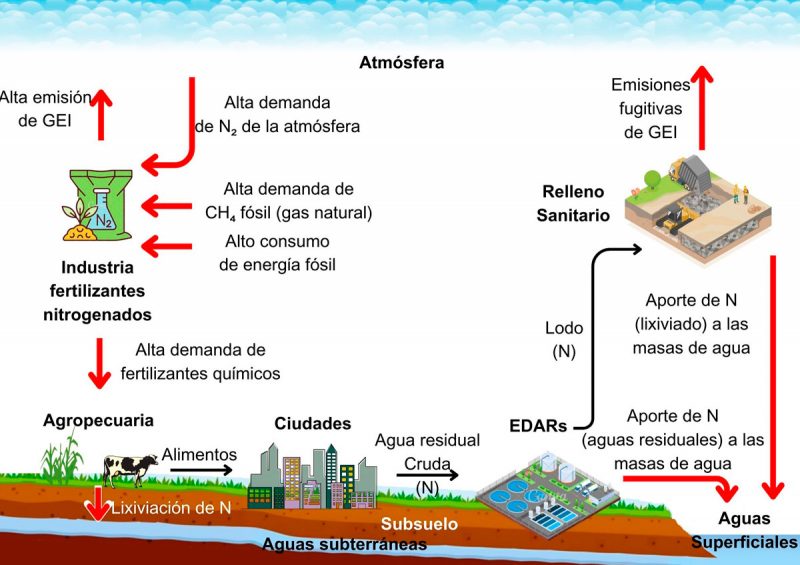

Conventional route – linear economy

Conventional route – linear economy

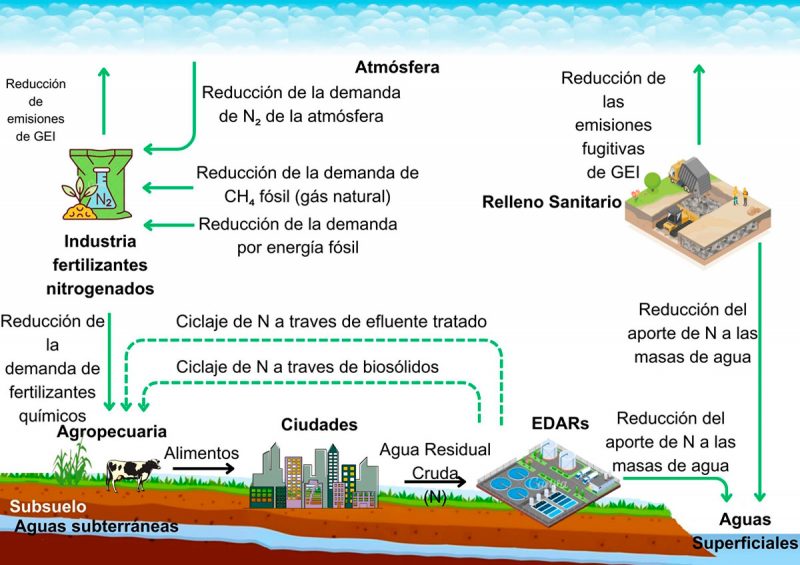

Route with recovery and use in agriculture – circular economy

Route with recovery and use in agriculture – circular economy

Nitrogen flows in relation to nitrogen fertiliser production

The concept of circular economy can be applied, for example, through the use of dewatered sludge and effluents generated and treated at WWTP. The recovery of nitrogenous compounds from effluent and sludge ultimately reduces greenhouse gas (GHG) emissions, the demand for chemical fertilizers and the supply of nitrogen to sustainable water bodies. The Water Environment Federation (WEF) has established the concept of “Water Resources Recovery Facility (WRRF)”, in which the WWTP is no longer considered a waste generator, but rather a factory of usable by-products.

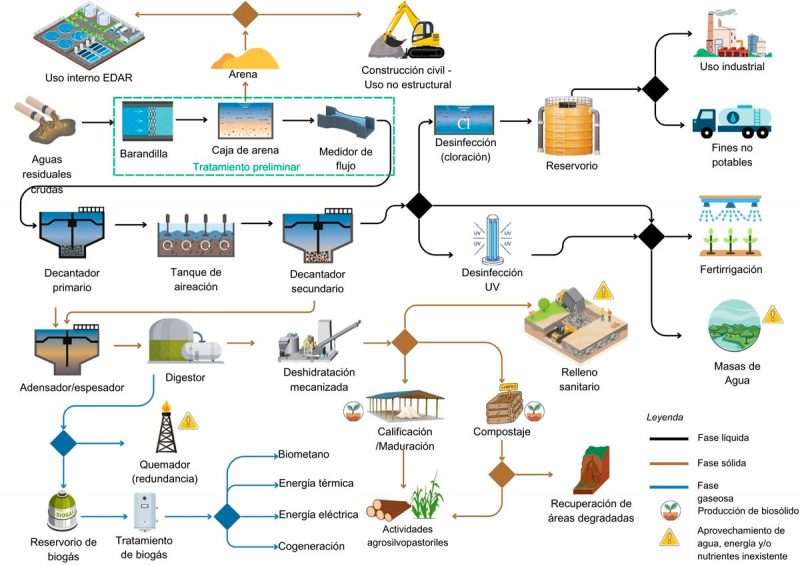

Possibilities for using wastewater treatment by-products

Possibilities for using wastewater treatment by-products

Based on this scenario, the São Paulo State Basic Sanitation Company (SABESP) contracted the preparation of studies and the conceptual design for the implementation of a circular economy model in the ABC and Suzano WWTPs -with treatment capacities of 3,500 m³/s and 1,500 m³/s, respectively-, works that ENGECORPS (in a consortium) has been carrying out since August 2024. Both WWTPs are located in the metropolitan region of São Paulo, an area characterised by municipalities with a high population concentration, including the most populated in the country, São Paulo, with nearly 11.5 million inhabitants (IBGE, 2022).

In mid-2024, SABESP went through a privatisation process and is currently managed by a private company. The arrival of a private entity in the management of the company naturally strengthened the focus on optimising wastewater treatment plants, energy efficiency, the use of clean technologies and, consequently, the extension of the concept of circular economy to other exploited treatment plants.

In this context, SABESP has requested the inclusion in the contract (under negotiation) of two other units, also located in the region: the São Miguel WWTP and the Barueri WWTP. The latter, with a treatment capacity of 16 m³/s, is the largest treatment plant in Brazil and one of the largest in Latin America.

This change aims to maximise the application of the circular economy model in the two stations, which currently have expansion projects underway. The São Miguel WWTP will increase its capacity from 1.5 m³/s to 5.5 m³/s, while Barueri will reach 22.5 m³/s at the end of the plan.

The contracted studies include physical and operational diagnosis phases, benchmarking and technological prospecting, focusing on the specificities of each WWTP, alternative studies and, in the case of the Suzano WWTP, the conceptual design of the selected alternative.

The SABESP Barueri WWTP, located on the left bank of the River Tietê.

The SABESP Barueri WWTP, located on the left bank of the River Tietê.

In the technological prospecting stage, the main and most promising technologies in use in Brazil and around the world are being identified and analysed. The objective is to obtain a complete overview of the solutions available worldwide to accelerate innovation processes at the plants, promoting greater efficiency in the use of resources in line with the Brazilian reality.

It should be noted that research on existing equipment and suppliers must focus on proven technologies in the sanitation sector, both in Brazil and worldwide, and applied on a real scale, considering aspects such as: market issues; acquisition and operating costs; energy efficiency; technical assistance, ease of maintenance and access to spare parts; lifespan of materials and equipment; mobility capacity (handling and transport of equipment) and modularity of equipment.

Specific surveys have been carried out for each phase of the treatment process (solid, liquid and gaseous) and, in addition, technologies have been verified for the generation of energy and the energy efficiency of the process, as well as the use of resources and the recovery of nutrients. Finally, procedures and technologies for the efficiency and optimisation of maintenance were also presented, with the aim of achieving the maximum use of WWTP assets and saving resources. The main processes indicated and evaluated were:

Solid phase: co-digestion, anaerobic digestion temperature, composting, thermal and solar drying, wetlands for sludge treatment, heat treatments such as pyrolysis, incineration and hydrothermal oxidation, phosphorus recovery from sludge ash, struvite precipitation, sand recovery from preliminary treatment, and nutrient recovery technologies for use in agriculture.

Gas phase: technologies for storage, removal of impurities (sulphides, VOCs, CO 2, siloxanes, etc.) and use of biogas (cogeneration of electricity and heat (CHP), gas boiler, sludge drying with biogas heating, production of biomethane and production of green hydrogen).

Liquid phase: biological removal of organic matter, nitrogen and phosphorus, physicochemical removal of phosphorus and organic filler, recovery of ammonia through membranes, etc. Potable (direct and indirect) and non-potable reuse technologies for treated effluents, such as irrigation, aquifer recharge and industrial uses, were also discussed.

Energy efficiency: measures to reduce energy consumption in wastewater treatment processes (aeration, pumping, sludge treatment, etc.) and processes to recover energy from internal sources, such as the use of biogas generated in treatment processes, and the incorporation of external renewable sources, such as solar photovoltaic systems.

Efficiency and optimisation of maintenance: use of IoT (Internet of Things) for monitoring and processing data, methods to identify imminent and recurring faults, measures to facilitate access to parts and supplies, as well as measures to increase safety in critical environments, among others.

Based on the technologies suggested in the technological prospecting stage, a study of alternatives can be developed to define the process to be adopted in each WWTP.

The evaluation of alternatives is being carried out with the support of modelling using the BioWinTM software, which makes it possible to model the chemical, physical and biological processes of WWTP. The main objective of modelling is to optimise the existing process, that is, to perform simulations of different operating conditions for the system to achieve certain efficiencies.

The final objective of the work is to define the ideal solution for treatment plants, with viable alternatives for the application of innovative solutions for plant optimisation, with a circular economy approach.

The conceptual design, which will be developed only for the Suzano WWTP, will contain the preliminary draft of all the proposed units and the business model guidelines for the products generated (reuse water, biogas, sludge, etc.).

At the end of the work, a synthesis report will be prepared summarising the studies, designs and technical documentation, constituting a basic document for dissemination. A technical guide will also be prepared for SABESP professionals, with guidelines for the design and implementation of new plants within the framework of the circular economy.